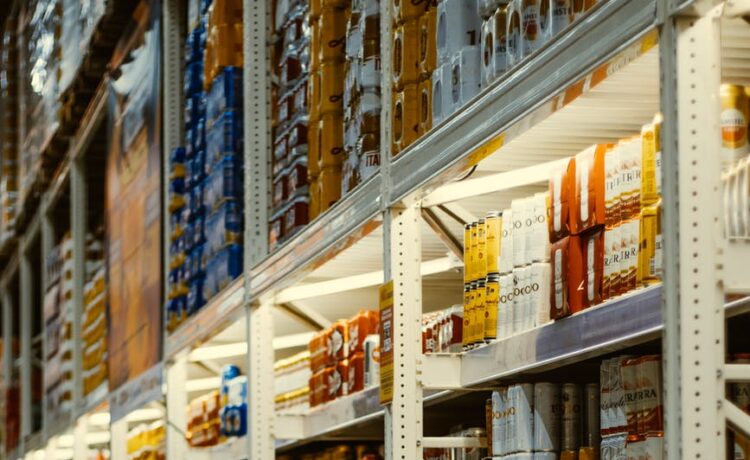

Pallet rack options can seem overwhelming when you’re trying to decide which one to buy. Should you get a new or used rack? What about color, size, and type? In this blog post, we’ll help you make a decision by outlining the key factors to consider when buying pallet rack. We’ll also give you some tips on how to choose the right one for your business.

What is a Pallet Rack?

In the world of industrial and commercial shipping, pallet racks play a vital role. Pallets are small, rectangular boxes that are used to stack items for transport. They can be either new or used. New pallet racks are typically much more expensive than used ones, but they may be worth the investment if you anticipate needing to use your rack often.

Used pallet racks can be a great option if you aren’t sure you’ll need a new rack in the future. They’re often cheaper than new racks, and they may already have some of the features you need (such as rails). If you decide you do need a new rack later on, using a used one is an easy way to get one without spending too much money.

What are the Advantages of New Pallet Racking?

There are many reasons to consider new pallet racking when purchasing a new warehouse or distribution center. Here are three key advantages of new pallet racking:

1. Increased Storage Capacity

New pallet racking is often designed with increased storage capacity in mind, which can help you meet your storage needs for large, bulky items. In comparison, used pallet racking may not have as much space available for larger items, which could lead to wasted storage space and additional costs.

2. Enhanced Safety and Security

New pallet rack systems are often built with enhanced safety and security features in mind. These systems typically include sensors that monitor the loading and unloading of pallets, as well as automatic locks that keep your inventory secure. Used pallet rack systems may not include these features, potentially leaving your inventory vulnerable to theft.

3. Improved Manufacturing Processes

New pallet rack systems are often manufactured using more advanced manufacturing processes that result in stronger, more durable units. Used pallet rack systems may not be as strong or durable, which could lead to failure in the long term and increased maintenance costs.

What are the Disadvantages of New Pallet Racking?

There are a few disadvantages to choosing new pallet racking over used. New rack systems are typically more expensive than used racks and may not be compatible with your existing equipment. Additionally, new racks require more installation time and can be more difficult to move around. Finally, if your business uses a lot of freight, new pallet racking may not be the best option because it is less durable.

How to Choose the Right Type of Pallet Rack for Your Business

When it comes to choosing the right type of pallet rack for your business, it can be hard to know what to look for. There are a lot of different options out there, and it can be tough to decide which one is right for you. Here are some tips on how to choose the right type of pallet rack for your business:

First, consider your needs. What do you need the rack for? Do you need storage space for large quantities of materials? Do you need a specific type of storage? If so, there are certain types of racks that are better suited for that purpose than others.

Next, think about your budget. How much money do you want to spend? Are new racks more expensive than used ones? That depends on the particular rack and where you buy it, but in general, newer racks tend to be more expensive than older ones.

Then, look at the features that are important to you. Do you need a heavy-duty rack that can handle a lot of weight? Or do you only need something that is lightweight and easy to move around? Some features that may be important to you include height adjustment (if needed), ability to lock or secure the racks from theft, and versatility – can the rack be used for other purposes besides shipping or storage pallets? For example, some racks can also be used as raised work surfaces in warehouses or production areas. Also you can use second hand pallet racking for your storage.

More information about New and second hand pallet racking in Australia

If you’re in the market for new or used pallet racking, there are a few things to consider. Here are some of the key factors to take into account:

– Weight capacity: The heavier the load, the more weight your rack can handle. Make sure the rack can hold your total expected load before you buy it.

– Material: Some pallet racks are made from metal while others are made from plastic. Metal racks are often more expensive, but they tend to be stronger and last longer. Plastic racks tend to be cheaper and easier to work with, but they may not be as strong or durable.

– Design: There are different styles of pallet racking available, so make sure you pick one that best fits your needs. Some racks have hooks on top to attach items like ladders or forklifts, while others have rails that run along the bottom of the rack.

– Construction: Look for a rack that is well-built and features sturdy construction. Pallet racking that is poorly designed or constructed may not hold up over time, which could lead to problems such as debris buildup or instability of your load.

New and second hand pallet racking in Australia

Pallet racking can be a great way to organize your storage space and improve efficiency. However, if you’re looking for new pallet racking, there are a few things to consider. New pallet racking is typically more expensive than used pallet racking, but it could be worth it if you plan to use the rack for a long time.

If you’re only planning on using the rack for a short period of time, then used pallet racking may be a better option. You’ll likely save money by buying secondhand pallet racking instead of new pallet racking, and you won’t have to worry about depreciation or wear and tear.

Both new and used pallet racking are available in Australia. If you’re looking for a specific type of pallet rack (e.g. metal or plastic), be sure to do some research before making your purchase.