Precision and customisation are very important for a variety of industries and this is critical for laser cutting as well. You can be working in a creative field or in manufacturing; but it is important to ensure the quality and precision you expect is provided by the laser cutting services.

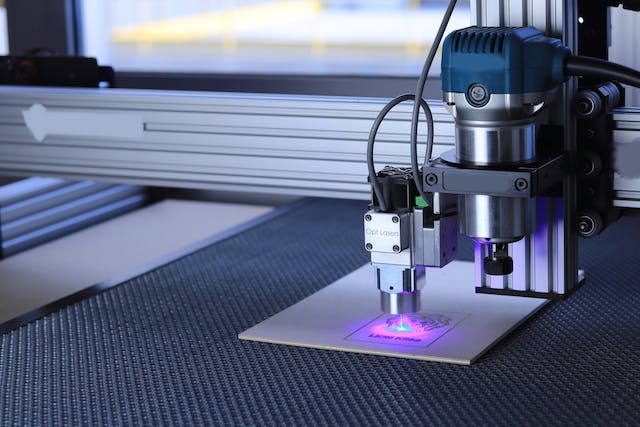

When choosing a company for laser cutting Sydney you have to consider their reliability and expertise. This is a specialised field and you need to work with professionals that have a thorough understanding of laser equipment, different materials and cutting techniques. You can get an idea of their experience by visiting their official website. You can also reach out to them to ask about the range of materials that they can cut. Some examples of these materials are wood, metals, plastics etc.

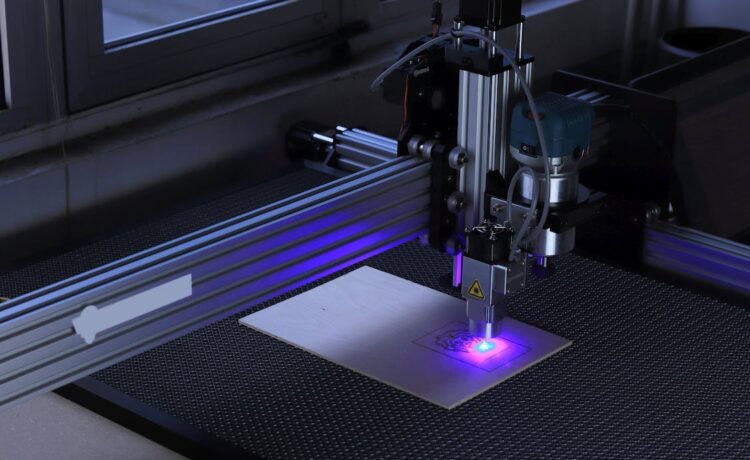

By choosing a company with sufficient experience, you will have some peace of mind that they are able to handle the demands of unique projects. You need to check whether they use cutting edge technology in their operations. You can ask about the type of laser cutting machines they have and whether these are up to date with the innovations of the field. By choosing a company with state-of-the-art laser cutting machines, you can ensure the precision of the process. This will allow them to cut intricate designs with ease.

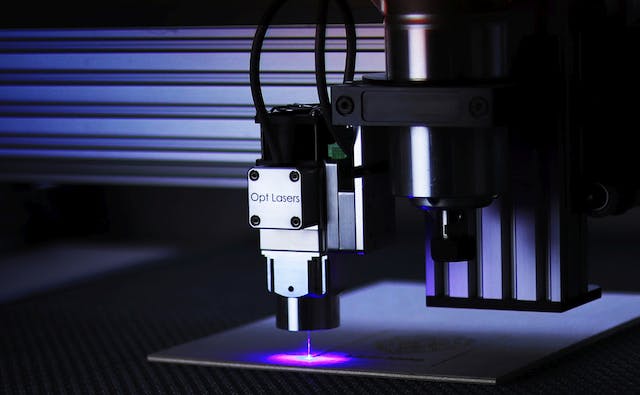

Different laser cutting approaches are required for different materials

When choosing a laser cutting company, you need to check whether they have experience with a wide variety of materials such as plastics, acrylics, composites and wood. You need to consider the track record of the company when cutting materials. Ask about their expertise when it comes to the material requirements of your project. Sometimes clients will come with finalised designs while others will need more assistance with their designs. Some will be looking for prototyping services.

So you need to check whether the laser cutting company provides support in the design phase. This allows you to refine your design and optimise it for laser cutting. Prototyping services can be very useful when evaluating the feasibility of the laser cut parts. This will help you adjust the larger scale production.

Precision is critical for laser cutting

And you need to consider the tolerance levels that can be achieved by the custom laser cutting company. This will have a big impact on the quality of the finished project. You need to ask about their tolerance levels and precision so that you can ensure the final components meet the specifications of the project. Ask about their production capabilities and capacity. If you have a large project, it is important to check in advance whether they are able to handle the volume of work you have in mind for the specific time period. The production process should be efficient and scalable so that the demands of your project can be met. Ask about the quality assurance of the process. This can include inspections during the process, testing procedures to ensure precision of each cut and final inspections.