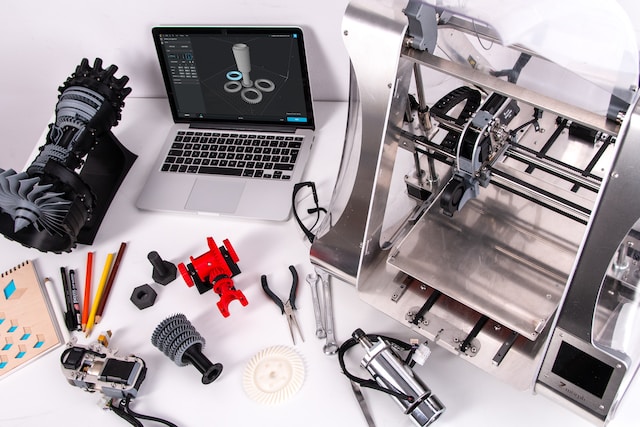

To produce three dimensional objects out of digital designs which we once saw only in research settings is today a transformate force in manufacturing, health care, architecture and also the arts. Over the past few years 3D printing has grown from a fancy hobby into a work day solution for many industries. In Australia we have seen large scale growth in this field which is supported by innovation centers, government programs and also a large scale demand for local on demand production.

Rise of Additive Manufacturing in Australia

Australia has embraced 3D printing with open arms, enjoying its capability to spur innovation and reduce foreign manufacturing. Universities, research centers and private organizations have all played their part in pushing the limits of what can be achieved with this technology. Everything from implants to medical devices to aerospace components has been researched and utilized by Australian organizations using 3D printing solutions. Melbourne and Sydney are the centers of technological innovation, where start-ups and established companies are investing in additive manufacturing to increase productivity and sustainability.

Industry Leaders and Innovation

With the technology having matured, so too has the requirement for specialist services. This is where Formero Australia comes into play. As a leading 3D printing service company, the business has helped bridge the gap between digital design and production. By offering services from rapid prototyping through to small batch manufacturing, Formero Australia has helped customers from various industries like automotive, medical and consumer products. Their advanced features allow Australian businesses to introduce new goods to the market and innovate faster without incurring exorbitant overseas manufacturing prices.

Applications in Healthcare and Medicine

The progress of 3D printing in Australia can be observed from the increased utilization of 3D printing in the health industry. Hospitals and research centers have spearheaded the usage of 3D printing in patient specific models, surgical planning, and prosthetic manufacture. Australian doctors are already using printed-out anatomy models to practice complex operations in order to increase patient gains and reduce procedure lengths. 3D printing is also making bespoke implants and prosthetics more accessible because local firms are producing devices to meet unique specifications. The technology also holds the potential for being explored in bio-printing applications in which human tissue and organs could be printed in the future for use as transplants or research.

Impact on Education and Research

In Australia we see that education and research are very much at the forefront of 3D printing adoption. Across the country universities have reports that they have included 3D printing in their engineering, architecture and design programs which in turn is giving students first-hand experience with the technology. Also researchers are using 3D printing for prototyping which in turn is to reduce the time and cost which is usually associated with traditional fabrication methods. In fields like archaeology and paleontology 3D scanning and printing is a game changer which allows researchers to reproduce and study fragile artefacts without in any way damaging the original. This is a blend of innovation and access which in turn is the foundation of a new generation of Australian thinkers and problem solvers.

Sustainability and the Future

Sustainability is a hot topic in the 3D printing industry in Australia. The technology itself reduces waste by only using the material needed for each object, unlike subtractive manufacturing processes. Companies are experimenting with biodegradable materials and recycled plastics to make 3D printing more eco-friendly. As Australia tackles climate change and goes for a circular economy 3D printing is a solution for localised, sustainable production. Looking forward advancements in material science and printer technology will open up even more opportunities for Australian industries to stay competitive in a rapidly changing world.

3D Printing in Australian Manufacturing and Defence

Beyond healthcare and research 3D printing is making a big impact in Australian manufacturing and defence. Traditional manufacturing in Australia has faced challenges with global competition and high production costs. But additive manufacturing is a viable alternative by allowing custom, low volume production runs that are cost effective and efficient. Industries such as automotive, mining and aerospace are using 3D printing to create bespoke components, tools and prototypes. In defence the ability to manufacture mission critical parts locally is invaluable especially in remote or high stakes environments.